Introduction

The automotive industry is undergoing its most significant transformation in a century, shifting from internal combustion engines (ICE) to electric vehicles (EVs). A top-5 global automotive OEM, producing over 8 million vehicles annually, faced a critical bottleneck in scaling EV production: battery supply chain fragility.

The company relied heavily on single-region suppliers in Asia for lithium, cobalt, and nickel, exposing it to geopolitical risks, shipping delays, and raw material price volatility. When supply chain disruptions during the pandemic cut battery availability by nearly 30%, EV launch timelines were delayed, and market share was lost to faster-moving competitors.

To sustain growth, the OEM engaged a consulting-led initiative to build supply chain resilience through nearshoring, recycling integration, and digital supply chain optimization.

Challenge

-

Single-Source Dependency

-

Over 80% of lithium and 70% of cobalt sourcing came from a single region.

-

Price volatility increased raw material costs by 42% in one year, directly impacting margins.

-

-

Production Delays

-

EV launch schedules were pushed back by 6–9 months, giving competitors an edge.

-

Plant utilization dropped to 65% capacity.

-

-

Regulatory Pressure

-

New ESG regulations in Europe and North America required stricter sourcing transparency.

-

Penalties loomed for failure to disclose supply chain emissions.

-

-

Sustainability Gap

-

Customers increasingly demanded greener EVs.

-

The OEM’s lack of battery recycling capabilities threatened long-term competitiveness.

-

Solution

The consulting engagement rolled out a multi-pronged resilience strategy:

-

Diversified Sourcing & Nearshoring

-

Partnered with mines in South America and recycling firms in Europe to reduce reliance on one region.

-

Established joint ventures with local gigafactories in North America and Europe.

-

-

Circular Economy Integration

-

Invested in battery recycling plants to recover lithium, cobalt, and nickel.

-

Created a closed-loop supply chain, reducing virgin material demand by 20%.

-

-

Digital Supply Chain Twin

-

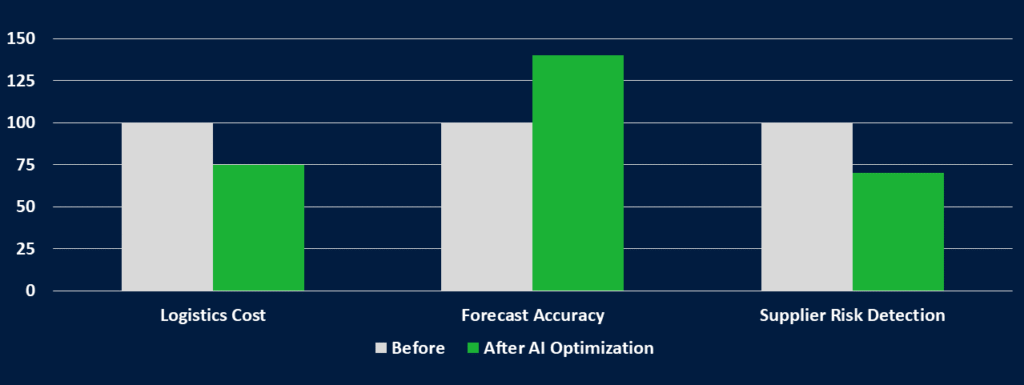

Implemented a cloud-based digital twin to simulate disruptions, track supplier performance, and optimize logistics routes.

-

Enabled predictive analytics to forecast shortages months in advance.

-

-

Sustainability & ESG Compliance

-

Embedded blockchain for traceability of raw materials, ensuring ethical sourcing.

-

Published transparent carbon reports to meet EU ESG standards.

-

Results

-

Supply Chain Resilience

-

Reduced dependence on single-region suppliers by 45% in two years.

-

Secured long-term contracts with diversified partners.

-

-

Cost & Margin Optimization

-

Lowered raw material cost volatility by 28%, stabilizing EV margins.

-

-

Production Recovery

-

EV production capacity utilization rose to 92%, enabling timely launches.

-

-

Sustainability Milestones

-

Introduced first recycled-battery EV model, improving ESG ratings by 30%.

-

Achieved 15% reduction in Scope 3 emissions.

-

Strategic Insights

-

Circular economy integration is becoming non-negotiable in EV supply chains.

-

Nearshoring battery production improves resilience and aligns with regional incentives.

-

Digital supply chain twins are an emerging differentiator for predictive disruption management.