The global industrial landscape is undergoing a profound transformation, driven by the imperatives of quality, efficiency, and data-driven decision-making. At the heart of this shift lies Machine Vision (MV) technology, the engineering of optical non-contact sensing to receive and interpret real-world images automatically. No longer a niche automation component, Machine Vision has evolved into a cornerstone of modern industrial strategy. Executives must prioritize strategic investments in machine vision to capture value from emerging trends such as AI integration and sustainable manufacturing, while mitigating risks from economic headwinds.

The Strategic Market Landscape: Quantifying the Opportunity

The growth of the Machine Vision market is not merely a trend; it reflects its proven return on investment across diverse sectors. To establish a foundation of trust, we anchor our analysis in data from authoritative public and international bodies.

The global machine vision system market is demonstrating robust expansion. The market was valued at approximately USD 15 billion in 2024. The compound annual growth rate (CAGR) is projected to be a significant 14% over next decade, aiming to reach a projected value of around USD 37 billion by 2032.

This growth is not homogenous. The Asia-Pacific region consistently dominates, accounting for the largest market share, driven by the massive manufacturing bases in China, Japan, and South Korea, alongside increasing adoption in Southeast Asia. North America and Europe remain innovation powerhouses, with high concentrations of R&D and early adoption of AI-driven vision systems.

Global industrial robot installations remained large and an operational robot stock exceeding 4.5 million units, a proxy for broader automation and machine-vision TAM. Regional concentration remains high with Asia at nearly 75% of total installations.

Deconstructing the Key Drivers: Beyond Basic Automation

1. The Unrelenting Demand for Quality Assurance and Zero-Defect Manufacturing

In industries such as semiconductors, electronics, and pharmaceuticals, where a single microscopic defect can result in catastrophic failure, 100% automated inspection is non-negotiable. Machine Vision systems provide the speed, accuracy, and repeatability that human inspection cannot match, directly reducing scrap rates and warranty costs.

2. The Rise of Industry 4.0 and Smart Factory Initiatives

Governments and industry consortia worldwide, such as Germany’s “Plattform Industrie 4.0” and China’s “Made in China 2025,” are actively promoting the adoption of cyber-physical systems. Machine Vision is a fundamental data-acquisition node in the Smart Factory, feeding real-time quality and process data into Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems, enabling a closed-loop, self-optimizing production environment.

3. The Strategic Integration of Artificial Intelligence (AI) and Deep Learning

This is the single most transformative driver. Traditional rule-based vision systems struggle with unpredictable variations. AI-powered vision, particularly deep learning, excels at complex classification and anomaly detection tasks such as identifying cosmetic defects on textured surfaces or sorting agricultural produce. This expands the application scope of MV from precise measurement to cognitive inspection.

4. Addressing the Global Labor Skills Gap and Supply Chain Pressures

The chronic shortage of skilled labor in advanced manufacturing, coupled with post-pandemic supply chain volatility, has forced companies to invest in automation to ensure operational resilience. Machine Vision-guided robots (Robotic Vision) are pivotal in tasks like bin-picking, assembly verification, and logistics, mitigating labor dependencies and increasing flexibility.

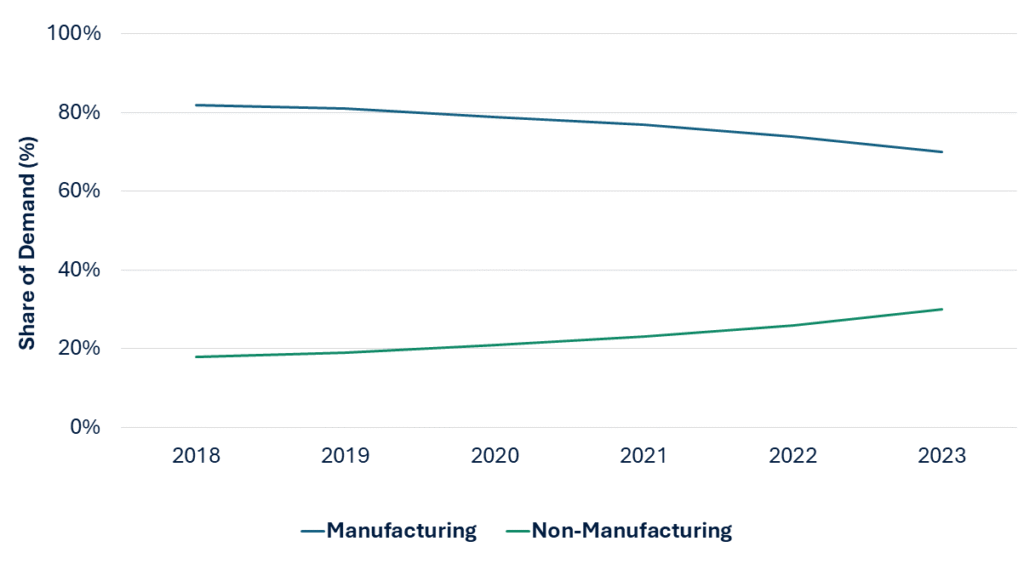

Machine Vision Demand Shifting Beyond Manufacturing (2018–2023)

Application Spotlight: Where is the Value Being Realized?

The application of Machine Vision is diversifying rapidly. The table below highlights key sectors and their primary use cases, demonstrating the technology’s transversal value.

Strategic Applications of Machine Vision Across Industries

|

Industry Vertical |

Primary Application |

Strategic Impact |

|

Automotive |

Robotic guidance for assembly, weld inspection, 3D gauge verification. | Ensures safety-critical quality, enables flexible production lines for electric vehicles. |

|

Electronics & Semiconductor |

PCB assembly inspection, wafer defect identification, component placement. | Essential for miniaturization, yield management, and high-volume production. |

|

Food & Beverage |

Quality grading, packaging integrity check, label verification. | Protects brand reputation, ensures compliance with food safety regulations (e.g., FDA, EU). |

|

Pharmaceuticals |

Blister pack inspection, vial label and cap integrity check. | Guarantees patient safety, enforces strict traceability and regulatory adherence. |

|

Logistics & Warehousing |

Parcel sorting, dimensioning, optical character recognition (OCR) for reading. | Drives efficiency in e-commerce fulfillment, optimizes warehouse space and throughput. |

Future Outlook and Strategic Recommendations

The trajectory of the Machine Vision market points toward even greater integration and intelligence. We anticipate the convergence of MV with other data streams, such as thermal imaging and vibration sensors, to create multi-modal inspection systems. Furthermore, the rise of edge computing will process vision data closer to the source, reducing latency for real-time control applications.

For business leaders and strategists, the implications are clear. To capitalize on this momentum, we recommend the following actions:

-

-

- Conduct a Process Audit: Identify bottlenecks in your quality control, logistics, and assembly processes where human inspection is the limiting factor or a source of error.

- Pilot AI-Based Solutions: Do not limit your evaluation to traditional rule-based systems. Initiate pilot projects for complex inspection tasks that were previously considered “not automatable” using deep learning tools.

- Build In-House Expertise: The successful implementation of MV systems requires a blend of optical, software, and domain-specific knowledge. Invest in cross training your engineering teams or establish partnerships with specialized system integrators.

- Prioritize Data Integration: View your Machine Vision system not as an isolated island of automation but as a rich data source. Ensure new investments have the capability to seamlessly integrate data into your broader operational intelligence platform.

-

Conclusion: Strategic Imperatives and the Path Forward

The trajectory of the global Machine Vision Systems market is one of sustained and intelligent growth, transitioning from a specialized tool for automation to a foundational pillar of the data-driven enterprise. Its expansion is propelled by the non-negotiable demands of modern industry: absolute quality control, operational resilience, and the integration of AI for cognitive tasks.

The technology is no longer confined to the factory floor but is a strategic asset that feeds critical intelligence across the entire value chain, from production and packaging to logistics and supply chain management. Organizations that continue to view it as a mere cost center will inevitably fall behind in both efficiency and innovation.

To secure a competitive advantage, leadership must adopt a proactive and strategic approach to Machine Vision integration. The focus should be on:

-

-

- Prioritizing AI and Deep Learning: Move beyond traditional rule-based systems to tackle complex inspection challenges and unlock new levels of process understanding.

- Building Cross-Functional Expertise: Foster collaboration between operational technology (OT) and information technology (IT) teams to ensure vision systems are seamlessly embedded into the broader data architecture.

- Initiating Targeted Pilots: Identify high-impact, high-return processes for proof-of-concept projects that can demonstrate clear ROI and build organizational buy-in for wider adoption.

-

The integration of advanced Machine Vision is a definitive step toward achieving operational excellence and market leadership.

Ready to transform your operational quality and efficiency? Let our consulting team conduct a high-level process audit to identify your most impactful Machine Vision opportunities.