Introduction

Green hydrogen is rapidly emerging as a critical component of the global energy transition, offering a zero-carbon alternative for hard-to-decarbonize sectors like steel, cement, chemicals, and heavy transportation. According to the International Energy Agency (IEA), the green hydrogen market could reach $300 billion by 2030, with production capacity expected to grow nearly tenfold.

Despite its potential, green hydrogen adoption faces significant operational and logistical challenges. Production is energy-intensive, requiring electrolysis powered by renewable energy. Transporting hydrogen is complex due to its low density, cryogenic requirements, and high-pressure storage needs. Additionally, fragmented supply chains, lack of traceability, and inefficiencies in logistics increase costs and limit scalability.

Our client, a Fortune 500 energy company, sought a comprehensive supply chain optimization strategy to reduce costs, enhance production efficiency, and secure industrial contracts in Europe and Asia-Pacific.

Challenges

-

High Production Costs:

Electrolyzers, while efficient in theory, often operated below optimal capacity due to fluctuating renewable electricity supply and maintenance constraints, leading to high per-unit production costs. -

Transport and Storage Complexity:

Hydrogen required cryogenic or high-pressure tank storage. Inefficient routing and partial truckloads increased costs by 15–20%. -

Lack of End-to-End Supply Chain Visibility:

Delays occurred due to poor coordination among production sites, logistics partners, and industrial consumers. -

Competitive Pressure:

Several competitors had already piloted large-scale projects. The client risked losing market share without a differentiated, cost-efficient solution. -

Regulatory Compliance:

Meeting international safety standards for hydrogen transport and storage was mandatory and required real-time tracking and traceability.

Solution: Digital-First Hydrogen Supply Chain

The consulting team implemented a multi-layered, technology-driven approach:

Phase 1: Blockchain-Enabled Traceability

-

Deployed a private blockchain network to record every batch of hydrogen from production to delivery.

-

Provided real-time tracking to ensure compliance with safety standards and quality assurance.

-

Enabled smart contracts for automated billing, reducing administrative overhead.

Phase 2: AI-Powered Logistics Optimization

-

Machine learning algorithms optimized transport routes, tank utilization, and load planning.

-

Forecasted demand at industrial facilities using historical consumption data and IoT-based sensors at client sites.

-

Reduced empty runs and inefficient routing, improving overall cost-efficiency.

Phase 3: Electrolyzer Performance Analytics

-

IoT sensors monitored temperature, pressure, and energy input in real-time.

-

AI models predicted maintenance needs and potential inefficiencies, increasing uptime by 18%.

-

Integrated with renewable energy forecasts to maximize electrolyzer operation during periods of excess solar/wind generation.

Phase 4: Strategic Industrial Partnerships

-

Established hydrogen hubs near steel mills, cement plants, and chemical factories.

-

Partnered with port operators for streamlined import/export logistics.

-

Negotiated joint ventures to secure long-term hydrogen off-take agreements.

Results Achieved

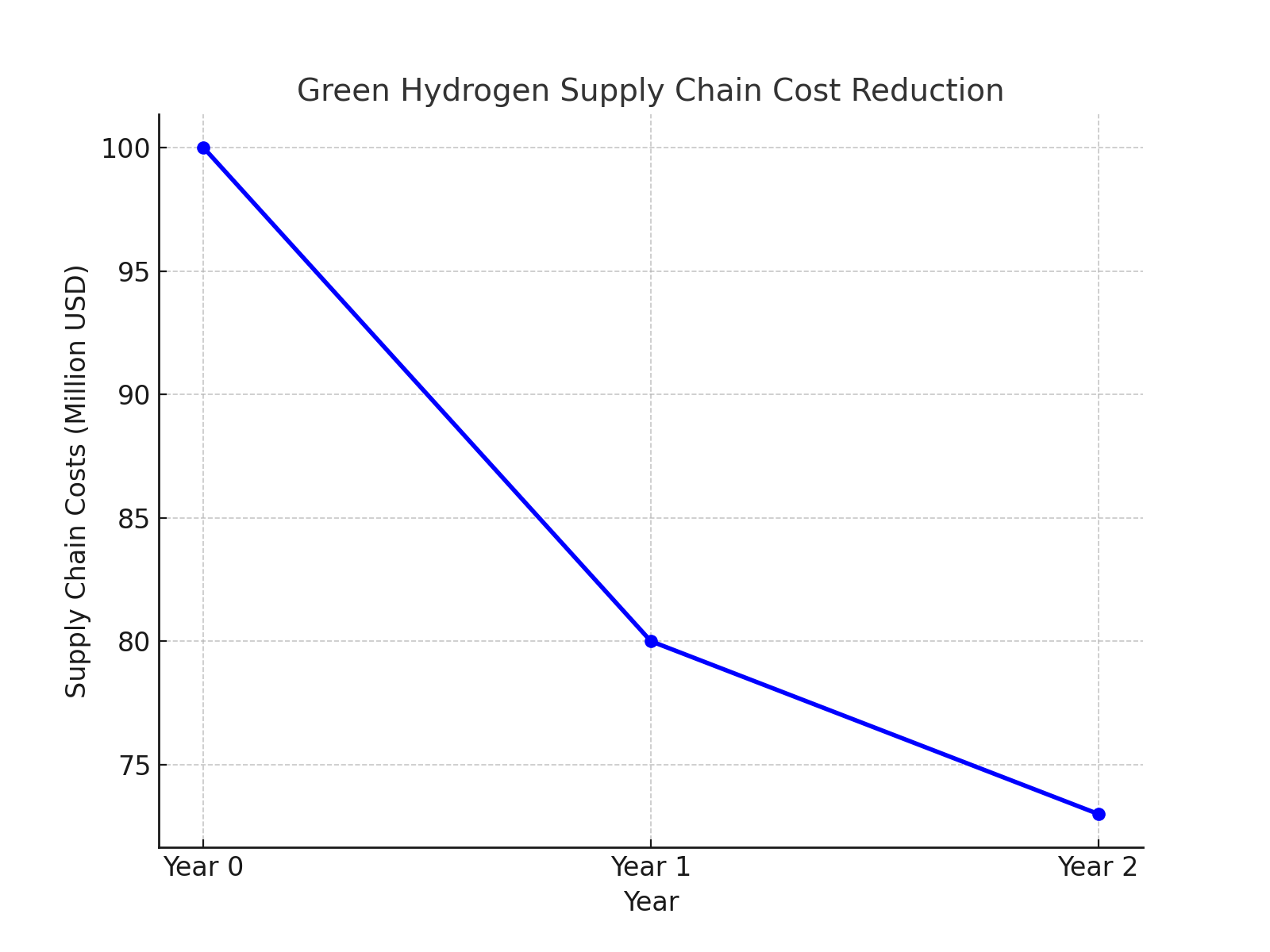

Within 24 months, the client achieved significant operational and commercial benefits:

-

27% Reduction in Supply Chain Costs: Optimized transport routes, improved tank utilization, and predictive maintenance drove cost efficiency.

-

35% Increase in Production Capacity: Electrolyzer uptime optimization and integration with renewable power allowed more consistent production.

-

Delivery Lead Time Reduction: Industrial clients now receive hydrogen shipments in 4 days instead of 12, improving project reliability.

-

$1.2 Billion in New Contracts: Industrial clients were attracted by reliable supply and transparent tracking, increasing off-take agreements.

-

Enhanced ESG Compliance: Blockchain traceability and efficient transport lowered carbon footprint, aligning with sustainability goals.

Competitive Benchmarking

| Approach | Cost Efficiency | Delivery Time | Production Uptime | Customer Confidence |

|---|---|---|---|---|

| Traditional Supply Chain | Moderate | Long | 80% | Moderate |

| Semi-Digital Optimization | Good | Moderate | 85% | Good |

| Full AI + Blockchain Solution (Client) | Excellent | Short | 95% | High |

The client emerged as a leader in green hydrogen supply chain innovation, surpassing competitors in cost, reliability, and scalability.

Strategic Insights

-

Blockchain Ensures Trust and Compliance: Real-time traceability reduces risk, builds customer confidence, and streamlines regulatory reporting.

-

AI Enables Predictive Optimization: Optimizing routes, storage, and electrolyzer performance maximizes efficiency and reduces costs.

-

Strategic Hubs Reduce Lead Times: Locating production near consumption points accelerates delivery and mitigates transport risks.

-

Sustainability Drives Market Advantage: Clients increasingly prioritize suppliers with low carbon footprints and transparent operations.

-

Future-Proof Supply Chain: Digitally integrated hydrogen supply chains are scalable, adaptable, and resilient against market fluctuations.

Future Outlook

-

Expansion of hydrogen corridors linking Europe, Asia-Pacific, and North America.

-

Integration of autonomous hydrogen transport vehicles and smart logistics systems.

-

Development of dynamic pricing models using AI to optimize supply-demand economics.

-

Scaling to industrial microgrids powered by hydrogen and renewable energy sources.