For over a century, the industrial playbook has been linear: Take, Make, Dispose. This model, focused on extracting virgin materials, manufacturing products, and sending them to landfills, has powered unprecedented economic growth. But it has also created unsustainable levels of waste, pollution, and resource depletion – costs that are no longer hidden.

Today, a profound shift is underway. Forward-thinking companies are moving beyond seeing sustainability as a compliance cost or a marketing initiative. They are recognizing it as the greatest operational innovation opportunity of our time. They are transitioning from a linear economy to a circular one, transforming their operations into a source of resilience, customer loyalty, and new revenue.

This isn’t about being “green.” It’s about being smart, efficient, and future-proof.

The Linear Burden: Why the Old Model is Breaking

The traditional linear model is inherently wasteful and risky. It operates on the assumption of infinite resources and landfill space, both of which are illusions. The consequences are stark:

-

-

- Resource Dependency: Companies are exposed to volatile commodity prices and geopolitical supply risks for virgin materials.

- Supply Chain Risk: Linear chains are fragile. A disruption in the supply of a virgin material can halt production entirely.

- Value Erosion: Over 90% of the materials used to make products become waste before they even leave the factory.

- Consumer & Investor Pressure: A growing majority of consumers prefer sustainable brands, and investors are increasingly mandating robust ESG (Environmental, Social, and Governance) disclosures.

-

Stat to Consider: Over 45% of global CO2 emissions come from how we produce and use products. Addressing this is impossible without a circular operations model.

The Circular Advantage: More Than Just Recycling

A circular economy is regenerative by design. It aims to decouple growth from the consumption of finite resources. It is built on three core principles, driven by operations:

-

-

- Eliminate Waste and Pollution: Rethink design and processes from the start to ensure no output is wasted. This is a design and manufacturing challenge.

- Circulate Products and Materials: Keep products, components, and materials at their highest value for as long as possible. This is a logistics and operations challenge.

- Regenerate Natural Systems: Return valuable nutrients to the environment, creating a positive footprint. This is a sourcing and supply chain challenge.

-

For operations leaders, this translates into four key strategic pillars:

1. Circular Design and Production:

This is the foundation. Products are designed for durability, repairability, disassembly, and recyclability. This involves:

-

-

- Using modular designs so components can be easily replaced.

- Selecting materials that are non-toxic and easily recyclable.

- Implementing manufacturing processes that generate minimal scrap, or finding uses for industrial by-products.

-

2. New “Product-as-a-Service” (PaaS) Business Models:

Instead of selling ownership, companies sell performance or access. Think of Philips selling “light as a service” to airports rather than lightbulbs. This aligns the company’s incentive with product longevity and efficiency, as they retain ownership of the materials. Operations must adapt to manage the reverse logistics, maintenance, and refurbishment of these assets.

3. Mastering Reverse Logistics:

The most complex operational shift is building a “reverse supply chain” that is as efficient as the forward one. This involves:

-

-

- Creating seamless return channels for end-of-life products.

- Developing sophisticated sorting, testing, and disassembly facilities.

- Determining the highest-value pathway for a returned item: repair, refurbish, remanufacture, or harvest for parts.

-

4. Regenerative Sourcing:

Procuring renewable, recycled, and recyclable inputs. This closes the loop and ensures that materials continually flow through the economy rather than being used once and discarded.

The Tangible Business Case: Beyond Idealism

The circular model is not a charitable act; it is a competitive strategy with a clear financial ROI.

-

-

- Cost Reduction: Using recycled materials can be cheaper than virgin materials. Remanufacturing products can require 50% less energy and 80% less virgin material than building new ones.

- Revenue Growth: Circular models open new revenue streams from refurbished goods, spare parts, and service contracts. It also attracts sustainability-conscious customers.

- Risk Mitigation: Diversifying material sources to include recycled content reduces exposure to price volatility and supply shocks for virgin resources.

- Innovation & Competitive Advantage: Companies leading the circular transition are building deep expertise and IP that competitors lack.

-

Stat to Consider: The circular economy could generate $4.5 trillion in new economic output by 2030. This is a massive value-creation opportunity.

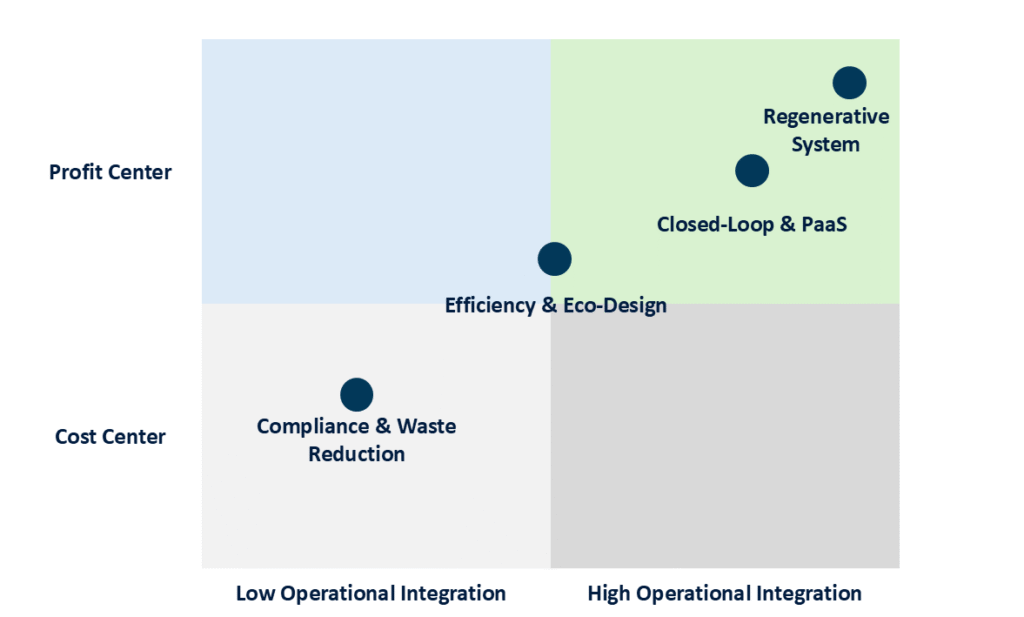

The Operational Maturity Journey: A Visual Framework

Transitioning to a circular model is not an overnight flip of a switch. It’s a strategic journey that requires building new capabilities. Companies typically progress through stages of maturity, as visualized below:

The Circular Operations Maturity Journey

Getting Started: Your First Steps on the Circular Path

The complexity of this transition can be daunting. The key is to start with focused, high-impact pilots.

-

-

- Conduct a Materiality Assessment: Identify the “what and where” – your most material waste streams, most valuable embedded resources, and most costly virgin inputs.

- Map Your Value Loops: For a key product, trace its entire journey and identify where value is lost. Where does it go at end-of-life? Can you get it back?

- Pilot a Reverse Logistics Program: Start with one product line or one region. Build the process for taking it back, learn from the challenges, and scale.

- Explore Partnerships: You can’t do it alone. Partner with recyclers, refurbishers, and even competitors to create industry-wide ecosystems for material collection and reuse.

-

Conclusion: The Linear Chain is Liability. The Circular Loop is an Asset.

The question is no longer whether your operations should become circular, but how and how quickly. The companies that succeed in making this strategic pivot will not only future-proof their businesses against resource scarcity and regulation but will also unlock unprecedented efficiency, innovation, and customer value. They will stop managing waste and start managing assets.

Is your operations strategy built for the linear past or the circular future? Let’s build a strategy that turns your waste into worth.