For decades, the supply chain management was simple: optimize efficiency, minimize cost, and drive lean, just-in-time operations. The cascading disruptions of recent years have exposed the fragility of hyper-optimized, linear supply chains.

Today, business leaders are presented with a pivotal choice either continue to react to disruptions or proactively build the supply chain of the future. The 2030 supply chain will be a resilient, intelligent, and sustainable value network that serves as a primary source of competitive advantage. Based on our analysis and work with global clients, here are the five transformative trends that will define the supply chain of the next decade.

1. From Linear Chains to Connected Ecosystems: The Rise of Hyper-Visibility

The traditional linear “chain” is evolving into a dynamic, multi-enterprise ecosystem. This shift is powered by technologies like IoT sensors, blockchain, and AI-driven platforms that create a seamless flow of information across suppliers, manufacturers, logistics providers, and customers.

The goal is end-to-end visibility, moving from reactive problem-solving to predictive exception management. Imagine not just knowing a shipment is delayed, but receiving a proactive alert that a weather event in the South China Sea will delay a key component, with your system automatically calculating the impact on production schedules and suggesting alternative routes all before the ship ever encounters a storm.

Organizations with high levels of supply chain visibility report a 15% lower cost to serve and hold 20% less inventory than their peers with low visibility. This isn’t just about risk mitigation; it’s a direct driver of efficiency and cost savings.

2. Intelligence Everywhere: The AI and Automation Revolution

Artificial Intelligence will move from a buzzword to the central nervous system of the supply chain. We are transitioning from using AI for isolated tasks (like demand forecasting) to embedding it into every core process:

-

-

- Predictive & Prescriptive Analytics: AI will not only predict disruptions but also prescribe optimal responses, automating decision-making in everything from inventory stocking to dynamic routing.

- Warehouse and Logistics Automation: Robotics Process Automation (RPA) and autonomous mobile robots (AMRs) will handle repetitive tasks, while AI optimizes warehouse layouts and pick paths in real-time, slashing labor costs and error rates.

- Smart Procurement: AI will continuously scan thousands of data points to assess supplier risk, predict price fluctuations, and identify alternative sourcing options instantly.

-

The human role will shift from manual executors to strategic overseers of automated systems.

3. The Resilience Imperative: Agility as the New Efficiency

The new paramount objective is resilience i.e. the ability to anticipate, adapt to, and rapidly recover from disruptions. This requires structural changes:

-

-

- Geographic Diversification: Companies are moving from single-source, offshore manufacturing to multi-regional sourcing strategies like friendshoring (sourcing from allied nations) and nearshoring.

- Strategic Stocking: The blind adoption of just-in-time is giving way to a smarter “just-in-case” model, where buffer inventory is held strategically for critical components, informed by AI-driven risk scores.

- Product and Process Design: Designing products for modularity and common components allows for greater flexibility in manufacturing and sourcing when disruptions occur.

-

Over 90% of supply chain leaders plan to make their supply chains more resilient, agile, and flexible. This is the number one priority on the boardroom agenda.

4. Sustainable and Circular Transformation

Sustainability is shedding its “nice-to-have” CSR image and becoming a core business driver, mandated by consumers, investors, and regulators. The linear “take-make-dispose” model is becoming obsolete.

The 2030 supply chain will be circular, designed to eliminate waste and continually reuse materials. This includes:

-

-

- Scope 3 Emissions Tracking: Companies will be held accountable for the greenhouse gas emissions of their entire value chain, demanding unprecedented data collection and collaboration from suppliers.

- Reverse Logistics Excellence: Building efficient systems for returns, refurbishment, remanufacturing, and recycling will become a standard capability, creating new revenue streams and reducing environmental impact.

-

Adopting circular economy principles could generate $4.5 trillion in economic benefits by 2030. Sustainability is directly linked to profitability.

5. The Talent Evolution: New Skills for a New Era

The technological transformation of the supply chain will fundamentally change the required skill sets. The demand for traditional manual logistics skills will decline, while the need for data scientists, AI specialists, automation engineers, and strategic analysts will skyrocket.

The most successful organizations will invest heavily in upskilling their current workforce and creating a culture of continuous learning. The supply chain professional of 2030 will be a tech-savvy, data-literate strategist who can manage AI tools and make complex, cross-functional decisions.

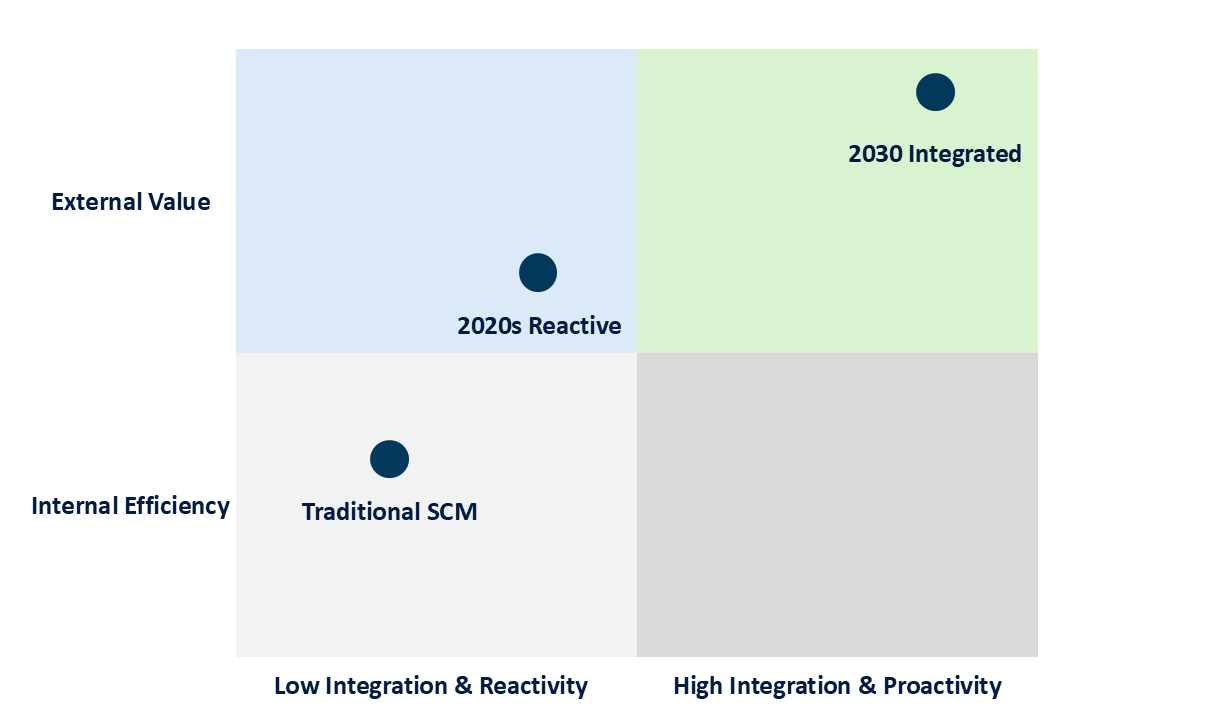

The Integrated Future: A Visual Summary

The 2030 supply chain won’t be defined by one technology or strategy, but by the integration of all these elements. Resilience is enabled by visibility; sustainability is powered by AI; everything is dependent on talent. This interconnectedness is captured in the model below:

The Evolution of Supply Chain Focus

Is Your Organization Prepared?

The journey to the 2030 supply chain is not a simple technological upgrade; it is a fundamental strategic transformation. It requires a clear assessment of current capabilities, a bold vision for the future, and a phased roadmap to get there. The question for leadership is no longer if you should invest in this future, but how quickly can you begin.

Start building your resilient and AI-powered supply chain. Contact us for a strategic assessment.