The term “Artificial Intelligence” often conjures images of sentient robots and science fiction. In the warehouse – an environment of concrete floors, rolling carts, and urgent deadlines – the reality is far more practical and profoundly more impactful. The hype around AI is deafening, but for operations leaders, the only sound that matters is the cha-ching of the cash register. The critical question is no longer “What is AI?” but “What is my ROI?”

The truth is, AI is not a futuristic concept; it is a present-day operational toolkit. It’s the silent force optimizing every square foot of your facility, every second of your labor hours, and every mile of your logistics network. Moving beyond the hype means understanding how AI-driven warehouses are achieving measurable, bottom-line results that leave their competitors behind.

The Warehouse Pressure Cooker: Why AI is No Longer Optional

Modern warehouses face a perfect storm of challenges: the demand for next-day and same-day delivery, chronic labor shortages, skyrocketing operational costs, and relentless pressure on margins. Traditional automation – like conveyor belts and fixed robots – addresses speed but lacks the cognitive ability to adapt, predict, and learn.

This is where AI steps in. It provides the adaptive intelligence that makes physical automation truly smart. It’s the difference between having a powerful muscle and having a powerful brain to direct it.

Stat to Consider: Companies that successfully implement AI in their supply chains can improve logistics costs by 15%, inventory levels by 35%, and service levels by 65% compared to slower-moving competitors.

Beyond Robotics: The Real-World AI Applications Driving Value

The most exciting AI applications are not always the most visible. They are the algorithms working behind the scenes, turning data into decisive action.

1. Predictive Analytics for Smarter Inventory Placement (Intelligent Slotting)

Gone are the days of static slotting based on gut feeling. AI algorithms analyze a multitude of variables in real-time:

-

-

- Historical Sales Data: What items are selling and when?

- Seasonality and Trends: Is a heatwave coming, increasing demand for specific products?

- Order Correlation: Which items are frequently bought together (e.g., a phone and a case)?

- Physical Attributes: Item size, weight, and packaging type.

-

By processing this data, AI dynamically slots products to minimize pickers’ travel time which can account for up to 50% of a picker’s shift. The result: a 20-30% increase in picking efficiency and a significant reduction in labor costs.

2. Digital Twins and Simulation

A digital twin is a virtual, AI-powered replica of your physical warehouse. This allows managers to simulate the impact of any change before implementing it.

-

-

- Test Layout Changes: How will rearranging aisles affect flow?

- Model Peak Season: Can your current setup handle a 300% volume increase during the holidays?

- Optimize Labor Scheduling: Precisely how many workers will you need for the next shift based on forecasted order volume?

This de-risks decision-making and unlocks unprecedented levels of operational planning.

-

3. Predictive Maintenance

Unplanned downtime on a sorter or automated guided vehicle (AGV) can bring operations to a halt, costing thousands per hour. AI changes this from reactive to predictive.

By analyzing data from IoT sensors on machinery (vibration, temperature, power draw), AI models can predict a failure days or weeks before it happens. Maintenance can be scheduled during off-peak hours, preventing catastrophic downtime and extending asset life.

Stat to Consider: Our study found that predictive maintenance can reduce machine downtime by 30-50% and increase asset lifespan by 20-40%.

4. Intelligent Labor Management & Safety

AI provides a data-driven approach to workforce management. It can:

-

-

- Forecast Labor Needs: Accurately predict daily and hourly labor requirements based on incoming orders.

- Optimize Task Assignment: Assign tasks to workers based on their location, current workload, and skill level, ensuring no one is idle.

- Enhance Safety: Computer vision AI can analyze video feeds in real-time to identify unsafe behaviors (e.g., not wearing proper PPE, incorrect lifting techniques) and alert managers before an accident occurs.

-

The ROI Spectrum: From Efficiency Gains to Strategic Transformation

The return on investment from AI materializes across multiple dimensions, evolving from tactical gains to strategic advantage.

The Efficiency Layer (Quick Wins):

-

-

- Labor Productivity: 20-35% increase in picking and packing speeds.

- Space Utilization: 10-20% better storage density through optimized slotting.

- Accuracy: AI-powered vision systems can achieve 99.99%+ order accuracy, virtually eliminating costly shipping errors and returns.

-

The Strategic Layer (Long-Term Advantage):

-

-

- Unprecedented Flexibility: An AI-driven warehouse can adapt to demand fluctuations in real-time, making it a competitive weapon during peak seasons.

- Scalability: It’s easier and more cost-effective to scale an intelligent system than a manual one. The AI can manage increased complexity without a linear increase in headcount.

- Data-Driven Culture: AI provides insights that empower continuous improvement, turning your warehouse from a cost center into a hub of innovation.

-

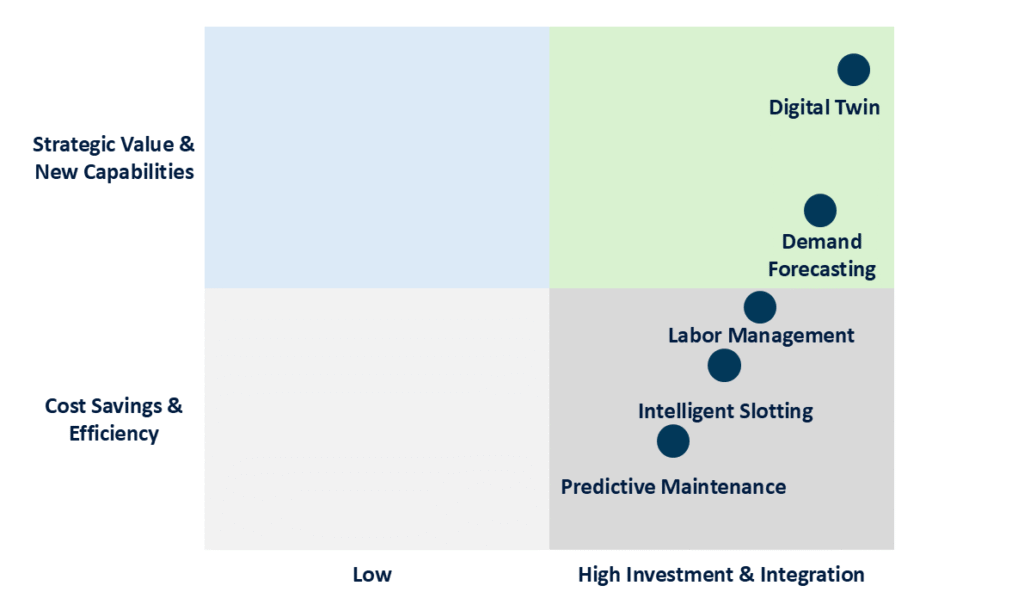

The following graph illustrates how investments in AI capabilities compound over time, shifting from cost-saving efficiencies to revenue-generating strategic advantages:

The Evolution of AI Value in the Warehouse

Implementing AI: A Pragmatic, ROI-First Approach

The path to AI adoption is not about buying the most advanced robot. It’s about solving your most expensive problems first.

-

-

- Identify Your Biggest Pain Point: Is it labor cost? Shipping errors? Space constraints? Start with a focused pilot project targeting that specific area.

- Assess Your Data Readiness: AI runs on data. You need clean, accessible data from your WMS, ERP, and equipment to fuel the algorithms.

- Partner for Success: Choose technology partners who focus on business outcomes, not just technology features. They should be able to clearly articulate the ROI model for their solution.

- Scale Incrementally: Prove the value with a single process or zone within the warehouse. Use the hard data and savings from that success to fund the next phase of rollout.

-

Conclusion: The Intelligent Warehouse is Here

The discussion has moved beyond automation to intelligence. AI in the warehouse is not a speculative future; it is a practical, proven, and profitable reality today. The gap is no longer between those who understand AI and those who don’t – it’s between those who are implementing it and those who are being left behind.

The investment is not just in technology, but in building a more resilient, agile, and profitable operation. The question for leadership is not if you can afford to invest in AI, but if you can afford not to.

Ready to calculate the specific ROI of AI for your warehouse operations? Speak with our supply chain technologists to build your phased adoption plan.